Roland Intelligent Pass Control Technology

Maximise Print Quality and Production

Roland Intelligent Pass Control™ is an exclusive patent pending technology that controls dot placement between passes of the print head to ensure smooth gradations, flawless solid colours and faster throughput. This results in increased productivity and exceptional image quality, even at higher print speeds.

Why Roland Intelligent Pass Control is Needed

Inkjet prints are created by the head of the printer making hundreds of passes back and forth across the media, depositing thousands of fine ink droplets at each pass and gradually building the image. The number of passes the printer makes depends on the set print resolution.

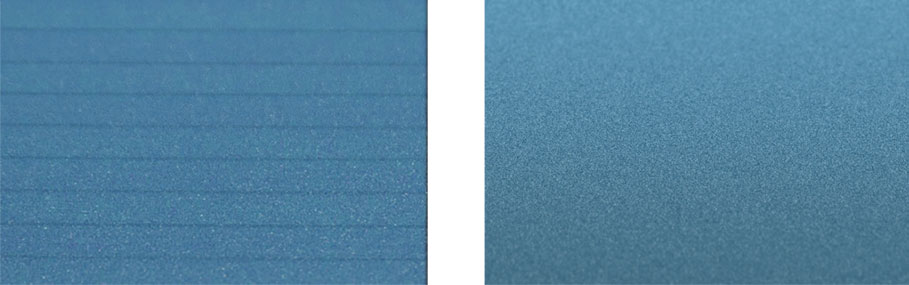

If the movement of the head and firing of the ink pattern are not optimised, the quality of the output may be affected. For example, bands of ink may be visible on the finished print, also known as “banding.” Banding can occur when there is a problem with the print firing, an incorrect amount of ink, or an issue with the media feed.

The "Intelligence" of Roland Intelligent Pass Control

Roland Intelligent Pass Control provides enhanced image quality in all resolutions through precise control of dot placement between passes, along with improved media feed compensation and ink levels control.

Optimised print firing patterns produce smoother gradations and flawless solid colours, tone density and image quality in every print mode, virtually eliminating banding. Thanks to Roland Intelligent Pass Control™ you can achieve faster throughput and high volume production on a wider range of media without compromising print quality.

Products that use this technology

|

|