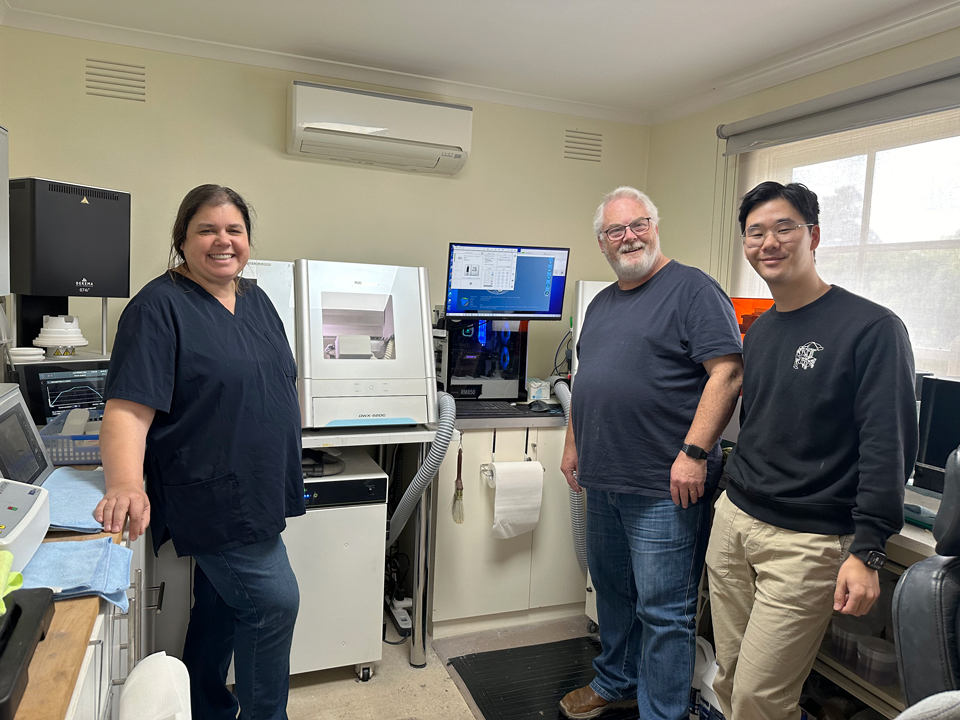

Golden Seal Dental Lab says their 'Golden Ticket' is an enduring focus on innovation

Golden Seal Dental Laboratory | Australia

Golden Seal Dental Laboratory is a highly regarded dental prosthetics laboratory with over 30 years’ experience, that supplies many of Melbourne’s leading dentists. Over the years, the business has earned a reputation for exemplary quality, aesthetics, and the ability to meet the most exacting customer expectations.

Golden Seal Dental Laboratory has always valiantly adopted new technology in the forms of digital scanners and CAD Software. In 2015, when their workload grew to such volumes that Russell was convinced they should bring their milling in-house, it was a straightforward decision.

Before

- Golden Seal was an early adopter of Digital Technology utilising various Digital Scanners and CAD Software since 1997, but always outsourcing the manufacture.

- 2014 brought a significant change with the purchase of a new Dental Lab Scanner and Design Software, however, still outsourcing the milling work.

- Outsourcing their milling meant they had little control over the materials being used and resultant quality.

After

- After outsourcing for a number of years, Golden Seal Dental Laboratory realised they had sufficient volume to add a milling machine to the existing technology, with the added benefit of using their preferred materials.

- With DGSHAPE Dental Mills, Golden Seal Dental Laboratory has the capability to create precise and high-quality dental prosthetics efficiently, from Zirconia, PMMA and other emerging Dental millable materials.

Golden Seal Dental laboratory specialises in all facets of crown and bridge prosthetics and has extensive experience in creating appealing custom restorations for large and small implant cases, Crowns, Bridges and Veneers using the latest technology, materials and techniques.

Their predisposition for adopting the newest approaches, combined with their depth of experience and in-house manufacturing capability, has made Golden Seal Dental Laboratory a leader in the supply of prosthetics with outstanding aesthetics and functional performance.

Russell Waycott is Director, Co-founder and Head Ceramist at Golden Seal Dental Laboratory, a highly regarded dental prosthetics laboratory in Melbourne, Australia. With over 30 years’ experience in the dental industry, Russell has remained at the forefront of prosthetics innovation across technology, materials and techniques during that time.

As one of the early adopters of CAD/CAM technology, Russell is a committed student of his craft who conscientiously maintains his vocational learning and attends international study tours when possible.

Taking control of their manufacturing has been a game-changer

Golden Seal Dental Laboratory has always valiantly adopted new technology in the forms of digital scanners and CAD Software. So in 2015, when their workload grew to such volumes that Russell was convinced they should bring their milling in-house, it was a straightforward decision.

Russell reached out to a number of colleagues to glean their feedback on the various types and brands of milling machines they were using, with varying degrees of success. But when he saw a demonstration of the DGSHAPE DWX-50 at a friends’ lab in Melbourne he found his solution “the rest is history”.

With tremendous support from his dealer securing and setting up his mill and software, Russell launched into dental milling and his laboratory expanded rapidly.

It’s been so successful that Golden Seal Dental Laboratory have since added a DGSHAPE DWX-51D and a DWX-52DC Dental Milling Machines to their operations to maximise production.

This expansion of services to include milling PMMA splints and dentures alongside zirconia crown and bridge, as well as implant-supported restorations, demonstrates Golden Seal Dental Laboratory's commitment to meeting diverse patient needs. By offering this service, the laboratory can provide comprehensive solutions for various dental restorative needs, ensuring they cater to a wide range of patient requirements. This expansion further solidifies their position as a versatile and capable dental laboratory.

Easy to use and maintain with great Service support

Russell is extremely pleased with his DGSHAPE devices saying “All of our DGSHAPE mills have been very easy to use and maintain. They produce very good quality work and our clients are very happy. They’re reliable and most importantly they provide consistent, quality output regardless of volume.”

All of our DGSHAPE mills have been very easy to use and maintain. They produce very good quality work and our clients are very happy. They’re reliable and most importantly they provide consistent, quality output regardless of volume.

Russell also praises the DGSHAPE service and support he receives saying “Software support is very good and makes working with their mills fantastic.”

Growing through consistency and experience

Russell is a strong advocate for DGSHAPE mills and would “strongly recommend them to others” but most importantly says he “hopes to purchase more DGSHAPE mills in the future” for his own laboratory.

There’s no greater endorsement than a business that continues to invest in a brand, and line of products, because they’re so clearly driving their business growth. We look forward to seeing how Golden Seal Dental Laboratory take any future DGSHAPE product advancements and apply them to their laboratory moving forward.

Learn more about the advanced features of DGSHAPE dental mills here.