DGSHAPE Announces New DWX-42W Abutment Kit for Effortless Titanium Milling

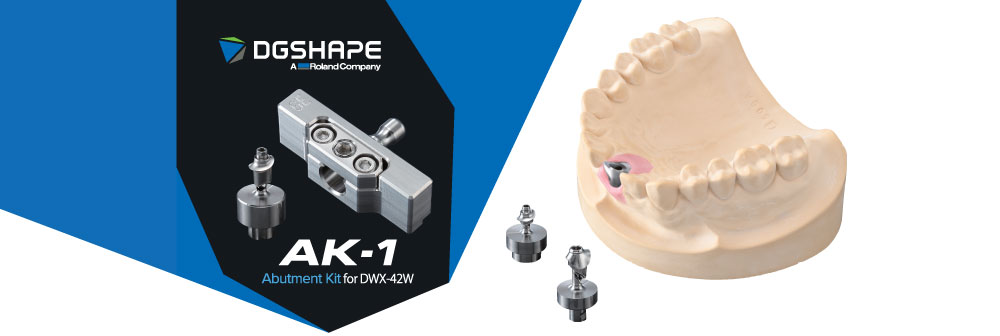

Sydney, Australia, July 7, 2020 – DGSHAPE Corporation, a subsidiary of Roland DG Corporation and a leading provider of digital solutions for dental laboratory technicians, announced today the release of the AK-1 Titanium Abutment Kit for the DWX-42W wet milling machine.

Increasingly, the adoption of digital CAD/CAM milling systems in place of traditional casting methods is becoming more widespread with dental laboratories. The DWX Series of dental milling machines by DGSHAPE Corporation specialises in the digital production of dental prosthesis such as copings, crowns, and bridges. DWX series milling machines can process various dental materials such as Zirconia, Wax, PEEK, and PMMA.

The new AK-1 Abutment Kit for the DWX-42W is a series of attachments to the standard DWX-42W material holder that produces high-value and effortless custom milling of titanium abutments from popular manufacturers such as GeoMedi, MEDENTiKA, and NT-Trading.

"DGSHAPE recognises that dental Implant treatment is regarded as a premium service offered by Clinicians," said Craig Davidson, Business Development Manager at DGSHAPE Australia. "Patients expect to receive implant restorations of a premium quality and therefore, Clinicians are moving from using stock abutments to custom abutments because they offer improved results. In order to meet the demand from our customers, the DGSHAPE DWX-42W is now able to produce custom milled Titanium abutments. This gives our customers an affordable solution and the opportunity to offer additional services to their customers.”

To begin milling custom titanium abutments in-house, simply attach the abutment adapter and change out the filtration tray and milling burs. The new specialised milling burs can process pre-milled titanium blocks with ease, for the effortless milling of quality titanium custom abutments.

For further detail, including data sheet details for the kit and specifications, please click here.