If you run an established signage or large-format print business, chances are you're always looking for opportunities to expand into new markets and drive more revenue. One production technology worth serious consideration is UV print and cut.

By adding UV print/cut capabilities, you can offer stunning new applications while building upon your existing equipment and expertise.

What’s Different About UV Print and Cut?

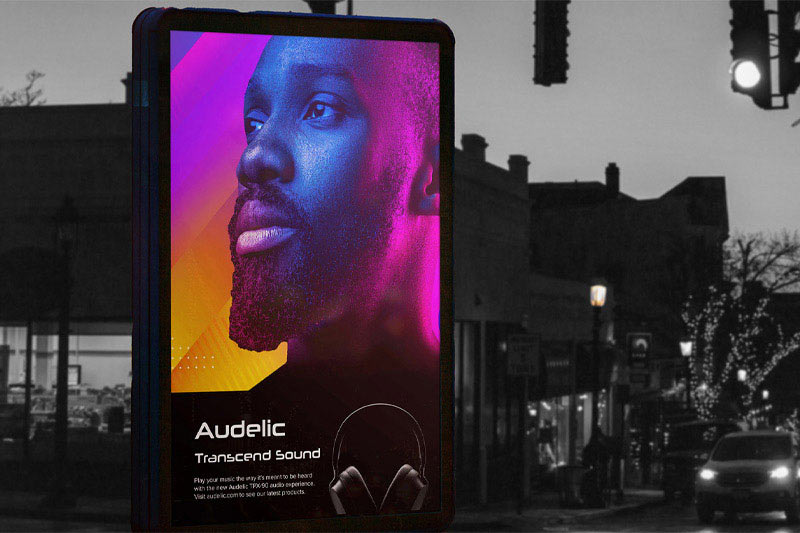

A POP display featuring a headphone brand

Print and cut is the foundation of many a print, signage or graphics business. Roland DG is a pioneer in the field that's traditionally built with eco-solvent or solvent ink print technology. Printing and cutting is a particularly versatile way of customising anything from packaging and decals to window graphics, signage, floor stickers and so much more. UV print and cut represents a departure from traditional print and cut, widening the range of products you can offer and, as a result, the customers you can attract.

As a complement to your existing setup, Roland DG UV printer/cutters deliver numerous capabilities geared to help you succeed, including:

- Integrated UV-LED low heat curing print and cut capabilities in one device, opening a wider range of substrates.

- Instant drying for rapid turnaround times.

- Exceptional colour density, gamut and vibrancy for matching challenging colours or printing clear substrates.

- RIP software tailored to maximising efficiency including the creation of white ink and gloss data with one click.

- Low VOC (volatile organic compounds) for eco-friendly indoor graphics printing.

UV inks cure (or dry) instantly when a UV light source passes over it once it’s printed onto the media, meaning it’s ready to be used or shipped immediately. The ink dries on top of the surface and isn’t absorbed into the material, resulting in a hard-wearing, ultra-durable finish.

What's more, adding cutting functionality creates an all-in-one print-cut workflow, allowing you to print vibrant graphics and then cut them into unlimited shapes and designs for finished printed products. You reduce production time and labour costs too, maximising throughput and turnaround time for customer orders.

Open New Revenue Opportunities with UV Print and Cut

UV print and cut allows you to take on higher-margin applications and sell more premium products due to the exceptional print quality and substrate versatility, creating opportunities for new revenue streams. You can sell durable custom products to an expanded customer base and earn repeat business in diverse industries such as hospitality, restaurants, retail, events, construction and manufacturing.

Here are some ways you can tap into lucrative revenue streams and into new industries while differentiating your business from competitors:

- Roll-to-roll UV production: Printing on flexible roll media makes high-volume production of labels, decals, vehicle graphics, wall graphics and floor graphics quick and easy. This high-throughput capability brings opportunities, with customers needing large print runs cost-effectively.

- Combining print and cut: The print-then-cut ability allows you to create precision-cut graphics, labels, decals, and intricately shaped displays/signage.

- New finishing services: You can offer unique services like creating raised textures and 3D effects through UV spot varnish ink printing. This can also be used to create a ‘doming’ type effect for medals and specialised stickers.

- White ink printing: Full opacity white ink allows printing on coloured or transparent substrates for unique backlit, day/night signage and graphics.

Expanded Customer Opportunities

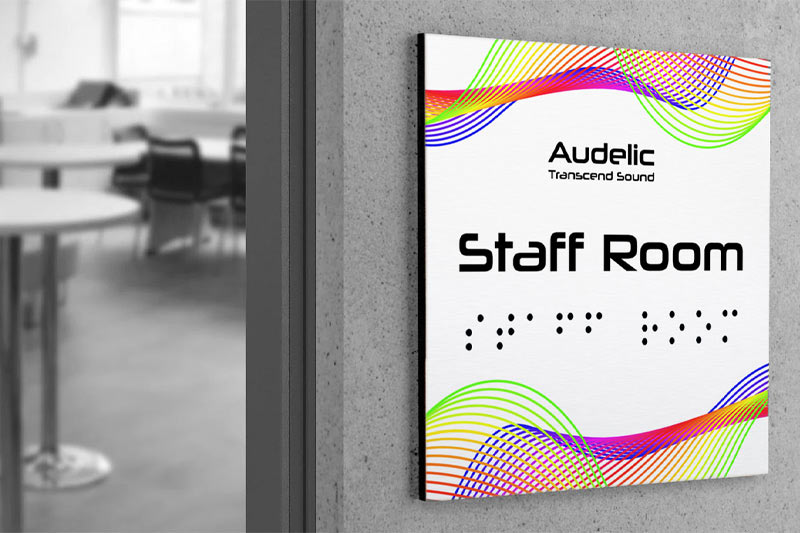

A braille staff room sign on a wall

If you can offer your customers a wider range of products and provide them with more solutions, you have an excellent opportunity to unlock new revenue streams.

Many customers are attracted by the durability and vibrant printing quality of UV inks for both indoor and outdoor graphics. UV prints provide excellent resistance to scratches, abrasion, and UV light for long-lasting results. You can combine printing on flexible substrates like vinyl, window cling, clear or optically clear materials, and semi-rigid cardstock with precise contour cutting to produce custom labels, decals, window graphics and more.

Here are some of our favourite methods of expanding customer opportunities:

- Packaging Prototypes: Print on vinyl to stick to a more rigid material or print directly onto semi-rigid cardstock to create packaging prototypes and mock-ups for clients in industries like consumer goods and pharmaceuticals.

- Interior Décor: UV ink is low in VOCs, meaning it is safe to be used indoors and around people and ideal for producing printed wall graphics, customised prints, photo prints and fine art reproductions.

- Industrial Printing: It’s possible to produce niche, small runs of specialist products, such as high visibility reflective safety signage or braille signage by building up multiple gloss layers, anti-slip floor graphics and way-finding signage.

- Labels and Decals: Print and cut labels/stickers on rolls or sheets for product labelling will always be a highly sought-after product, as will custom vinyl decals and vehicle graphics.

- Wide Format Graphics/signage: Print durable banners, window graphics and mesh that will stand up to time and the elements. Finish trade show displays and retail graphics with a matte finish that won’t cause glare in brightly lit environments.

Growth and Diversification

A backlit sign in the street

Adding UV print/cut capabilities allows your business to diversify and transform into a true full-service print provider offering more profitable large and small-format projects. You can make the most of your existing staff skills, customer relationships, and print expertise while greatly expanding your product portfolio.

With the right UV print/cut technology, you'll have the flexibility and versatility to take on a wide range of higher-value projects with faster turnaround. Not only can this lead to landing bigger customers and contracts, but you'll be better equipped to adapt and thrive as the print industry continues evolving.

Next Steps

Integrated UV printer/cutters provide production-level quality, speed, and efficiency, letting you expand into exciting new applications while continuing to grow your core business - the perfect next step toward sustained success in today's dynamic print environment.

If you have any questions about anything mentioned in this article, please get in touch with a Roland DG product expert.