Screen printing has long been a reliable method for creating high-quality prints on a wide range of surfaces. However, as technology continues to evolve, so do the expectations of consumers and businesses alike, resulting in businesses making a shift away from traditional screen printing in favour of digital UV inkjet printers.

If you currently rely on screen printing for the bulk of your print production, upgrading to a UV flatbed printer could be a smart strategic move to future-proof your business. In this article, we'll explore why an increasing number of businesses are making the switch and delve into the benefits and opportunities that UV flatbed printing brings.

Limitations of Screen Printing

A collection of used screens

Screen printing is the method of choice for many businesses because of its ability to produce items at scale. However, as with all print technologies, it also comes with drawbacks too.

- High Setup Costs – Screen printing involves the creation of physical screens for each design, which can be expensive, especially for small runs or multiple designs. Digital UV flatbed printing, on the other hand, is a digital process that can be easily configured for short or long runs.

- Limited Options – Traditional screen printing relies on a limited colour palette, making it challenging to achieve intricate or photorealistic designs. With Pantone colour matching and the Roland Colour Systems Library, it’s possible to hit a wide range of colours with a Roland UV flatbed printer. Additional colours, such as reds and oranges, can boost gamut while white inks can provide a solid base colour on a range of coloured substrates.

- Time-consuming – The process of setting up screens and applying ink can be time-consuming, leading to slower production times. With flatbed printing, you can simply set up the file and printer then let the printer take over and do the hard work.

- High Initial Investment – It can be difficult to get a return on investment with screen printing without producing at a scale that makes the initial outlay absorbable. This can also make the technology more difficult to introduce to new businesses that don’t yet require it.

- Waste and Environmental Concerns – Screen printing generates substantial waste, including excess ink, chemicals, and screens, which brings with it various environmental concerns. Conversely, UV flatbed printing entails printing ink directly to a substrate, reducing the need for wastage and can even be used to give a second life to products or offcuts.

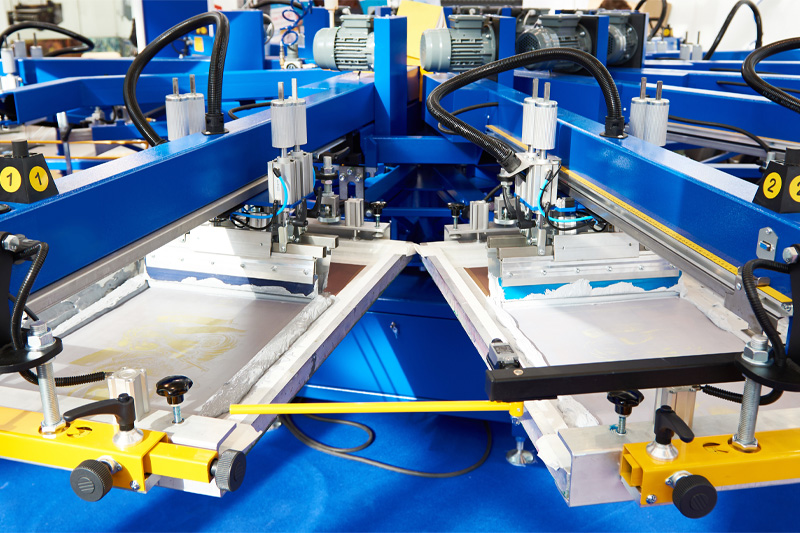

A large screen printer setup

For businesses that predominantly rely on high-volume screen print orders, these limitations may be manageable. But for shops looking to keep up with changing customer expectations and the growth in digital print technologies, it’s worth exploring the benefits UV flatbeds provide as an addition or alternative to screen printing.

UV Inkjet Printing

As mentioned above, with the advent of digital UV printing, many of the constraints associated with screen printing have been eliminated. This technology allows businesses to print directly onto a wide range of materials, including rigid substrates while providing several advantages that are revolutionising the industry.

It’s a huge leap forward in printing technology, using ultraviolet (UV) curable inks to create high-quality and durable prints on virtually any surface, including directly onto objects of various shapes and sizes. It’s the ideal technology for producing anything from signage, labels and packaging to personalised gifts, electronics, or even industrial components.

Advantages of UV Flatbed Printing

Digital flatbed printing provides a new way of doing what screen printing does, and more. This has introduced a variety of additional income streams for print businesses of all sizes.

Here are some of the biggest reasons why businesses are choosing UV flatbed printing over traditional screen-printing methods:

Versatility

Unlike screen printing, which requires separate screens for each colour, digital flatbed printing allows for full-colour printing in a single pass. This not only streamlines the printing process but opens new creative possibilities for intricate and detailed designs. The ability to reproduce high-resolution images directly onto a variety of substrates, including wood, glass, metal, and more, provides a level of flexibility that screen printing can’t match.

High-quality Output

UV flatbed printing provides exceptionally high print quality with vibrant colours, sharp details, and intricate designs. UV-cured inks produce vibrant and long-lasting prints that are both eye-catching and durable, making them suitable for indoor and outdoor applications. Businesses can take on a wider range of projects with complex, multicolour designs and intricate details. More interesting designs are likely to generate more interested customers.

A high colour canvas print on a living room wall

Personalisation and Short Runs

Personalisation is an industry trend that’s been steadily growing for years and shows no sign of stopping. Digital flatbed print is perfect for creating customised products, promotional items and limited-edition runs, so you can give the customer what they want, when they want it. Features such as variable data printing in Roland DG VersaWorks make this process easier and more accessible.

Speed and Efficiency

The UV flatbed printing process is notably faster than traditional screen printing. There’s no need for screen setups or drying times between colours, so the overall production time is significantly reduced. Increased efficiency not only boosts productivity but allows print businesses to meet tight deadlines and take on a higher volume of orders – ultimately translating into increased revenue.

Multiple pens on a flatbed

Scalability

As businesses grow, UV flatbed printing technology is easily scalable to meet increased or shifting demand. It’s not just about keeping up with technological trends, it's about future-proofing. Digital flatbed printing opens a wide range of markets and applications, from high-quality signage to customised home décor. It provides new income streams and means that businesses can adapt to an ever-changing market.

Cost-effectiveness

After the initial investment, the long-term cost-effectiveness of digital UV printing becomes apparent, most notably from the ability to print on-demand or one-off jobs. There’s less waste as you only use what you need, which helps to reduce overhead costs.

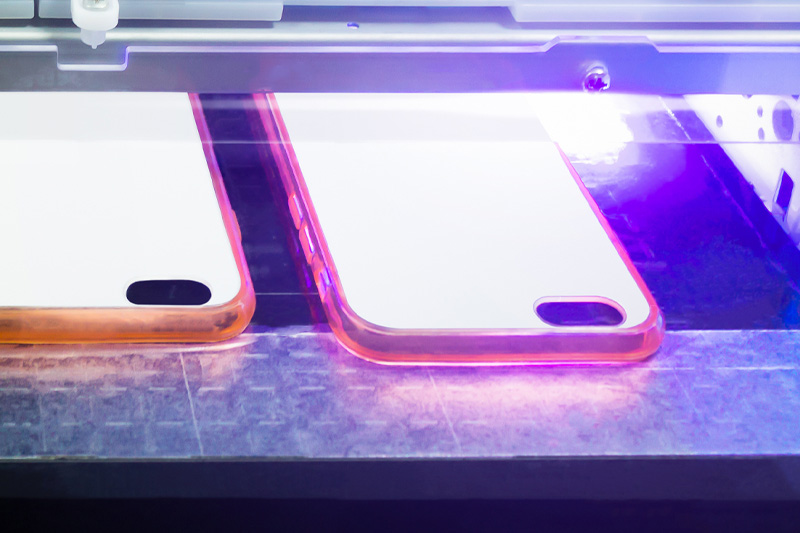

Phone cases under a UV light

Eco-friendly

Environmental sustainability is a growing concern for everyone. UV-cured inks produce little to no volatile organic compounds (VOCs) and generate minimal waste. Reduced setup times and material waste give UV printing one of the smaller environmental footprints.

Reduced Labour Intensity

Traditional screen printing often requires skilled labour to set up and operate the equipment effectively. UV flatbed printing is less labour-intensive and reduces the need for in-depth staff training thanks to a flatter learning curve.

What Should Your Business Consider Before Making the Change?

If your print business is contemplating the switch from screen printing to UV flatbed printing, there are some key considerations to keep in mind:

Equipment Investment

Evaluate your business needs, budget, and the range of materials you intend to print on to choose the right equipment for your plans. Strike a balance between your current needs and future growth plans.

Explore New Markets, Applications, and Opportunities

Think creatively and adapt to the changing printing industry. Offer a more extensive range of printing services and adjust your marketing and sales strategies to highlight the new capabilities and the improved quality of your prints, which should help attract new clients and retain existing ones. UV flatbed printing could prove to be an exciting complement or replacement for your current screen printing capability.

Sustainability

Is your customer driving change? Highlighting the environmental sustainability of UV flatbed printing in your marketing materials could be useful as it’s becoming a selling point for environmentally conscious customers.

Conclusion

The shift from screen printing to UV flatbed printing is not just a technological upgrade; it's a transformation that can redefine the capabilities and opportunities of your print business. The versatility, quality, efficiency, and cost-effectiveness of UV inkjet printing allows businesses to stay competitive and meet customer demands.

If you're considering making the switch or would like more information on anything we’ve covered in this article, please contact a Roland DG expert here.