If you work in the graphics industry, you’ll know how important colour accuracy is to customer satisfaction. But accurately matching colours to previous print runs, customer expectations, or how colours appear on screen is fraught with difficulties.

In this article, we take a closer look at the importance of getting colours right, linearization, ICC profiling and colour matching.

FROM SCREEN TO (SCREEN TO) PRINT

We all perceive colour differently (remember the black and blue dress conundrum that had the internet riled up for weeks?), and even if we were to find a perfect colour for our business, that shade is likely to undergo many transformations before ever being printed on a sheet of paper. It will look different from screen to screen, and especially from screen to print – because the colours you see on your monitor use red, green and blue light (RGB) to display colour.

In the world of printed ink, however, colours are generally composed of varying degrees of cyan, magenta, yellow, and black (CMYK), or other additional colours depending on your printer’s colour configuration. As such, there is always a process of conversion between your design and the final output, which poses a number of unique challenges. So how can you overcome these?

THE BENEFITS OF CONSISTENT COLOUR MANAGEMENT

Good colour management is the key to heightened productivity and efficiency. The ability to accurately reproduce and match colours will help you to:

1. Increase customer satisfaction

Customers want their logos and brand colours to look identical across time and mediums. Coca-Cola red and McDonald’s red may look similar to the human eye, but they’re not identical. Knowing how to deliver the colour your customers actually want is crucial.

2. Save time

It would be pretty inefficient if you had to rematch your customer’s brand colours for every single job, or after every physical device upgrade. That is why accurate colour matching will help you save a lot of time (and money) by allowing you to achieve the same output results across time and devices.

3. Reduce waste

Accurate colour matching limits the amount of reprints you need to perform to “get it right”, resulting in less waste, higher margins, and a healthier environment.

4. Let your business grow more naturally

Eventually, you may want to upgrade your current device or add a couple of new ones to your workshop. VersaWorks 6 includes an easy-to-use colour matching function to ensure consistent colour between multiple same-model printers when using the same ink type.

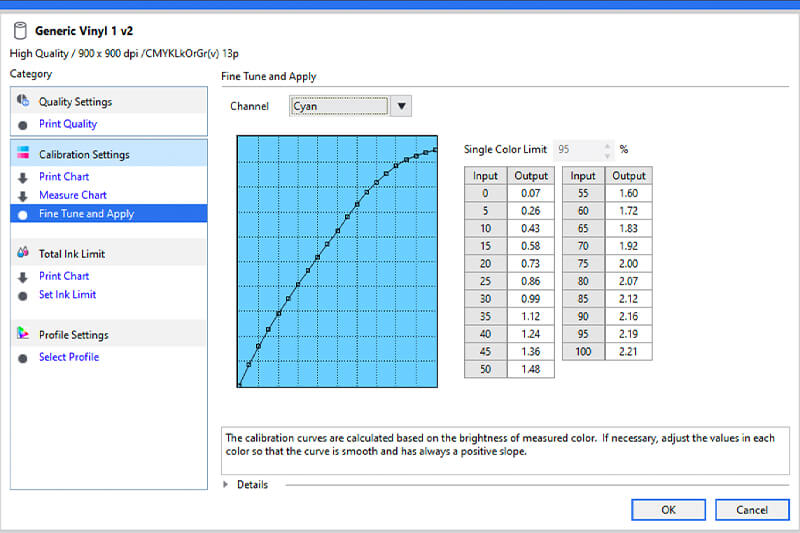

Colour management in digital printing is mainly built around two key aspects: linearization (or calibration) and ICC profiling on the one hand, and colour matching on the other. The main purpose of linearization is to define the best density primary colour-values from light to dark, while ICC profiling is about tonal (or spectral) colour values.

Or put more simply: to produce the right colours in the right amounts.

Colour matching is more about saving this data in some way, so that you can achieve the same output over time, whether on a single device or across various same-model devices using the same ink type.

LINEARIZATION AND ICC PROFILING

Most importantly, linearization and ICC profiling will help you set the optimal single and total channel ink limits for your device – thereby eliminating excess ink and ink bleeding on your media. These processes will ensure that your device outputs colours on a given media in exactly the way you’d expect.

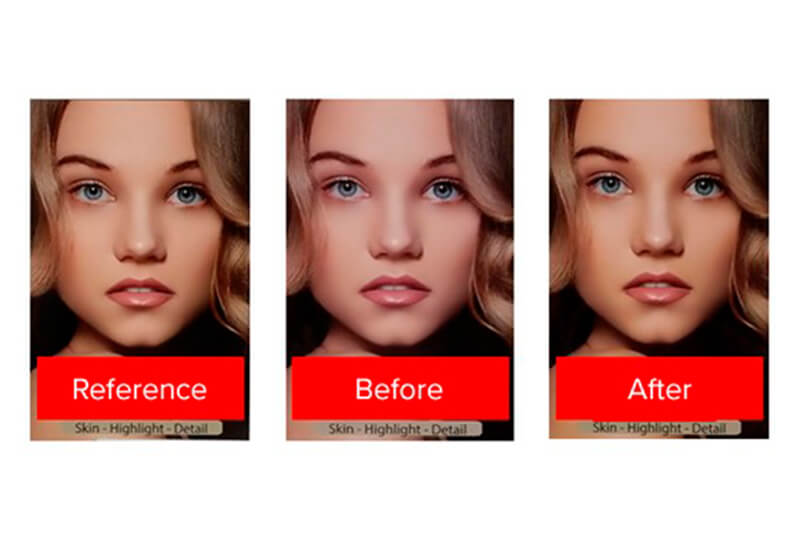

One key area where hitting the right tones of red, yellow, orange and magenta is crucial are skin tones. These are very complicated colours that your printer can easily get wrong. So you need to make sure that you’re not just using the best media for the job, but also the best settings and most ideal colour profile. This is essentially what linearization and ICC profiling do.

VersaWorks offers three different ways for finding the right linearization settings and ICC profile:

a) Generic profiles

VersaWorks comes preinstalled with a number of generic profiles, based on an average of measurements for a specific media type. These will include the correct linearization settings and the matching ICC profile for the indicated media. If you work with a standard vinyl from the hardware store, a generic vinyl profile in VersaWorks should be a great fit for the job.

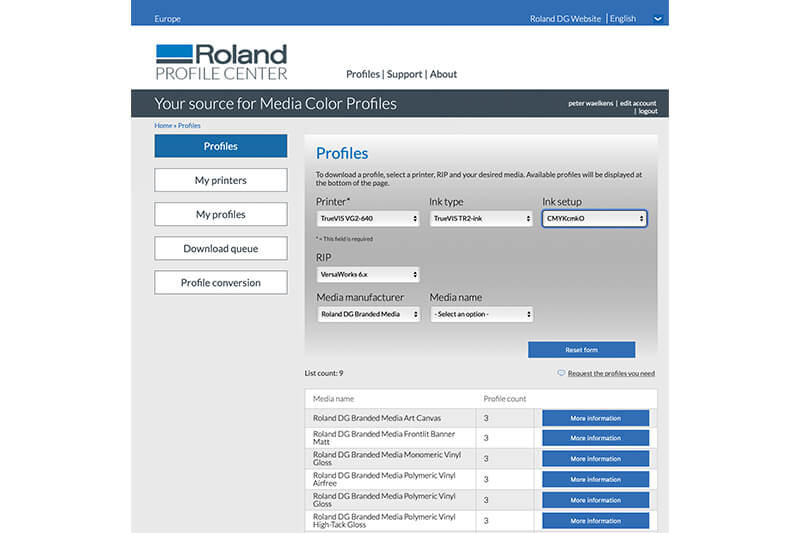

b) Roland Media Files via the Roland Profile Center

VersaWorks also supports a vast external library of ICC profiles, which can be downloaded from the Roland Profile Center. Registration takes only a few minutes and there is a wide range of profiles available for each of our printers, RIPs, and media from leading manufacturers such as 3M™, Avery Dennison, and HEXIS. These files also include the right linearization settings.

c) Create your own Roland DG media Files

Finally, you can manually linearize your device and create your own custom ICC profiles. While the linearization step can be done directly in VersaWorks, creating an ICC profile will require the use of third party software, like i1Profiler, and a third-party spectral measuring device, such as the X-rite’s i1 series or Barbieri’s Spectro LFP series.

Once you’ve found your ideal settings, you will want to store them somehow as this allows you to reprint files now and in the future with the exact same colour output quality. But how?

THE IMPORTANCE OF COLOUR MATCHING

This is where the third crucial step in the colour management process comes in: colour matching. It’s based on a simple concept: you linearize your device, pick an appropriate ICC profile, bundle these in a ‘media file’ (like those downloaded from the Roland Profile Center or the VersaWorks media library), and then use this to print a ‘reference file’ (also known as a ‘fingerprint’) and a target file.

This tells your printer that it should match your current and all future target files to this reference file. If you then print another target file a week, a month or even a year from now, on this or on another same-model device using the same ink type, your printer should perform the necessary adjustments to match your reference file.

VersaWorks 6 has always included a colour matching function for this reason, but historically, to get the full potential of this feature, you would have needed a spectral measuring device like the ones we mentioned earlier. The problem is that many people don’t actually need the full feature complexity of such devices to warrant their cost.

That is why we have recently launched the VW-S1 densitometer, a tool designed to make colour matching tasks faster and more accurate. In many regards, densitometers resemble spectrophotometers, except that they are easier to use, more affordable, and perfect for people who don’t wish to create custom profiles.

WHAT IS THE DIFFERENCE BETWEEN SPECTROPHOTOMETERS AND DENSITOMETERS?

The main difference is that spectrophotometers measure spectral values, like LAB values. RGB (Red-Green-Blue) and CMYK (Cyan-Magenta-Yellow-Black) modes reproduce colour by adding or subtracting it – thereby telling your computer or printer how much of each individual colour should be present in a particular spot. LAB (Lightness, green/red, blue/yellow) values on the other hand are based on a theoretical model that more closely resembles human colour perception.

While they are more accurate, they come with features and settings that many people will never use. Densitometers, by contrast, don’t measure colour values but the absence of reflected light, allowing them to provide very accurate information on ink densities and dot gain which you can use to fine-tune the amount of ink per colour.

Densitometers, like our VW-S1, tend to have a faster learning curve, cost less, and make the process of creating reference and target files simpler and quicker.

IS THE VW-S1 COLOUR MATCHING TOOL RIGHT FOR YOUR BUSINESS?

The VW-S1 allows you to easily match colour output over time or from two or more Roland DG printers with the same ink type, configuration and print settings. It’s the perfect choice for people who:

- Are satisfied with the ICC profiles available in the Roland Profile Center.

- Use multiple printers for large combined graphics.

- Have volume work for one or various specific return clients.

- Are looking for an easy-to-use density measurement device allowing them to save time and reduce waste by limiting the amount of reprints.

- Need to ensure consistent colour over time for reprint orders.

Don’t forget, however, that to use the new VW-S1, you will have to upgrade your device to the latest version of our VersaWorks 6.8 RIP, which includes many new features such as full support for the new VW-S1 tool, a ten-fold increase of the Variable Data Print limit, Simulation Profile Management, Multi Job Grouping and an updated Pantone library with no less than with no less than 294 new colours.

Further Your Skills and Knowledge with Roland Academy

To find out more about colour management, take a look at Roland DG's Training Solutions. These include courses on products, software, equipment and technical support. Our Roland DG Academy Training Courses can help you expand your skills and our RolandClinic sessions give you free advice and technical support.

You can download the latest version of VersaWorks at the link below.