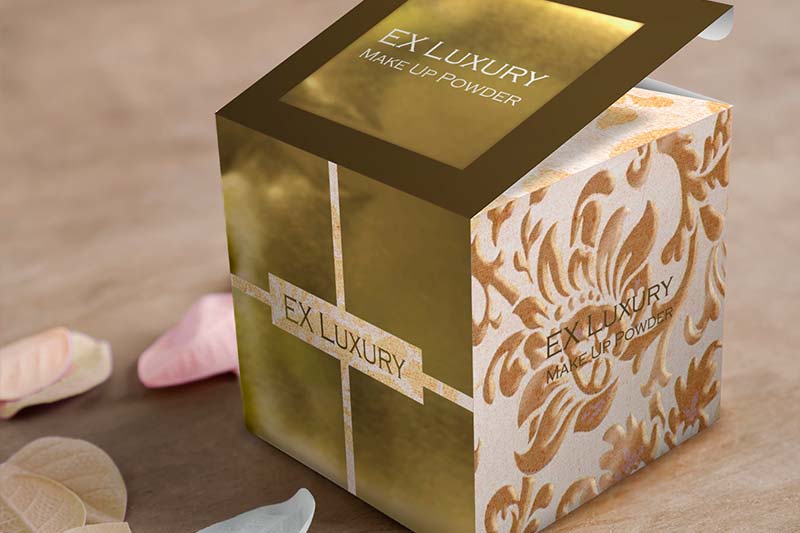

Packaging makes it possible to store, bulk handle, preserve, sell, and ship products without damage or loss of nutritional value. But it is not just functional: it’s also the first impression customers get about a product. Packaging can tell a story, evoke feelings, and add value to products. Whether it’s a shampoo bottle, a packet of sweets, or a box for high-end luxury items, packaging matters. And because it matters, it needs to be done right.

- Digital Solutions for Prototype Packaging & Labels

- Short Runs: Folding Cartons & Corrugated Packaging

- Produce Labels in Flexible Digital Micro Runs

- Discover New Digital Technologies

Digital Solutions for Packaging & Label Prototypes

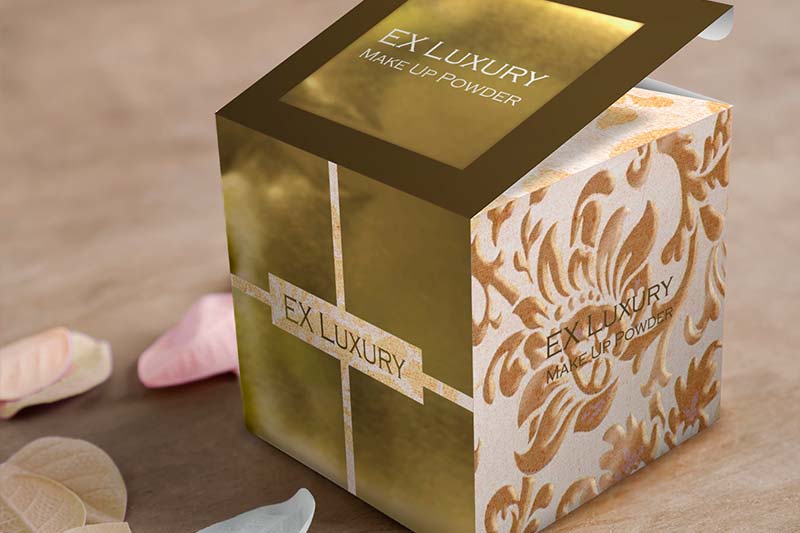

Whether you’re looking to create colour-accurate proofs or realistic mock-ups, colour management and substrate choice are the two key elements of the prototyping industry. But to create accurate mock-ups, complete with the staple effects of packaging (embossing, varnishing, and hot foil stamps) specialised proofing equipment is usually required, as well as the ability to print on original or extremely similar substrates.

This makes prototyping quite expensive and often wasteful. Digital printing technology has become increasingly popular in the packaging industry for this very reason. Its versatility, lower overall running cost, shorter time to market, and ability to simulate many of these staple effects, make it a viable alternative for a large variety of packaging prototypes.

Eco-Solvent

*Protoypes produced by CGS with Roland

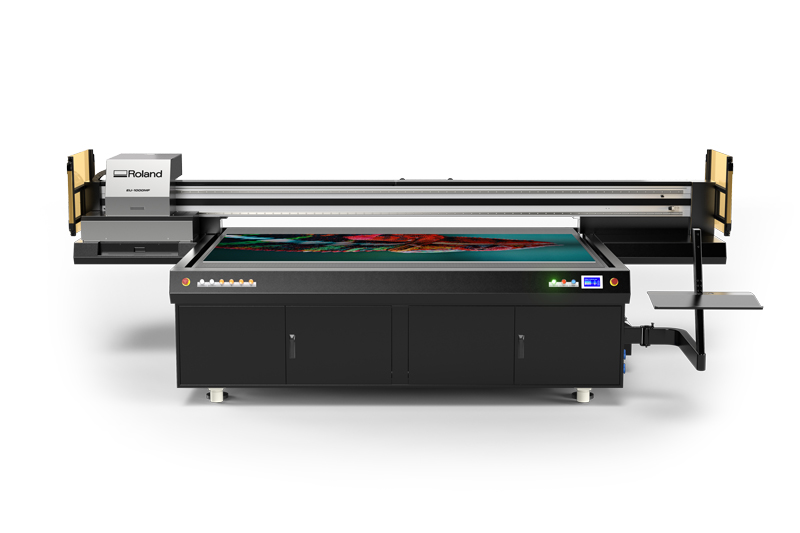

UV Technology

UV solutions come equipped with gloss, white and primer inks which allow for a wide range of special effects, including textures, simulated embossing and varnishing. Their main benefit is that they can print directly onto the original packaging substrates, but the colour gamut is usually smaller.*

*Protoypes produced by CGS with Roland

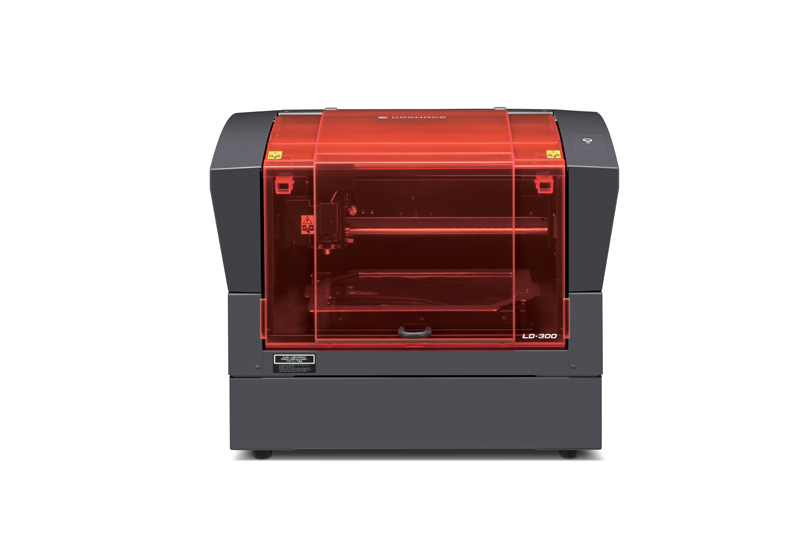

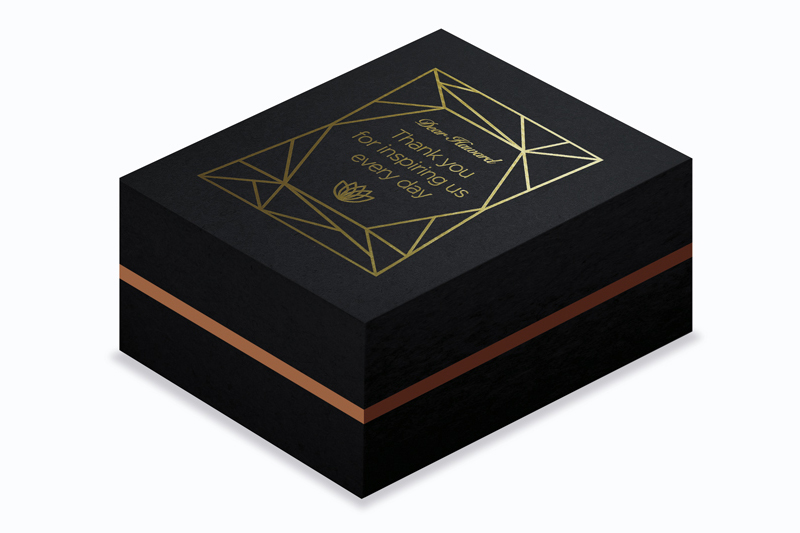

Laser Decoration

Laser Decorators can be used as a complimentary technology to produce foil effects for packaging prototypes – or even micro runs of personalised gift boxes. Laser decorators, like the LD-300, use a semi-conductor laser to apply heat activated adhesive foil to a variety of substrates. For proofing and personalisation, they are generally simpler, cleaner and safer to use than some traditional hot-foil stamping methods.

Short Runs: Folding Cartons and Corrugated Packaging

Flatbed UV devices can also be used to create short runs of folding carton or corrugated packaging. Some possible examples include

- Small runs of seasonal packaging

- Small volumes for new start-ups

- Trial runs of new packaging designs

- Limited editions for events

- Custom printed packaging

- Personalised packaging

A big advantage of using digital technology alternatives to produce very small runs, is that you can respond more quickly to small, last-minute requests, without having to interrupt or alter your production schedule. These solutions can also be appealing to brand owners or marketing firms looking to create short runs in-house.

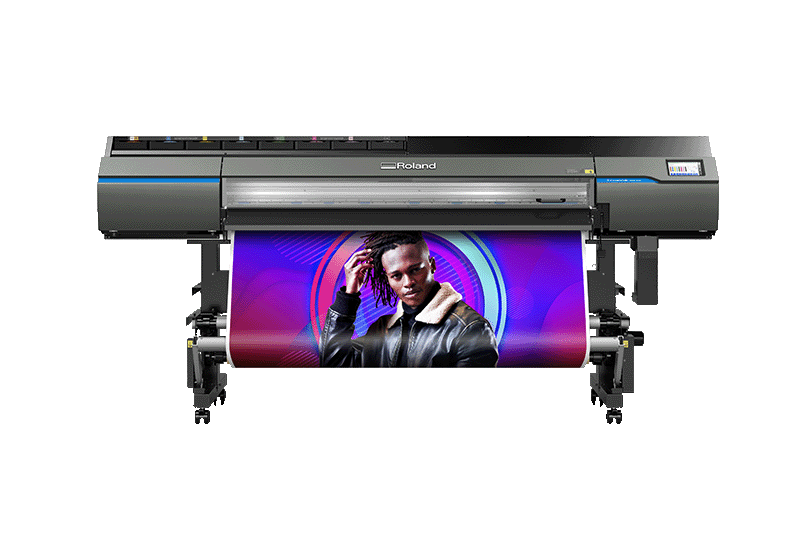

Produce Labels in Flexible Digital Micro Runs

Digital print & cut solutions are exceptionally well-suited to the production of micro run labels. While not as common as short runs, packaging professionals frequently receive requests for small amounts of labels, which can be quite challenging to produce when working solely analogue presses.

When working with a hybrid setup, such low volumes can be easily produced on a print & cut solvent printer, freeing up your flexographic printers for larger, more demanding jobs, while being able to satisfy customer demand.

Discover New Digital Technologies

Roland DG offers a wide range of powerful digital solutions that can help make your

packaging business more flexible, now and in the future.