Atlas Dental Studio are meticulous about every aspect of their laboratory, their production and their Roland DG mills

Atlas Dental Studio | Australia

Atlas Dental Studio is one of Perth’s leading crown and bridge laboratories renowned for its expertise in ceramic and implant restorations, specialising in e.max and zirconia restorations. Atlas Dental Studio is committed to integrating cutting-edge technology to produce the highest quality dental products.

The laboratory's dedication to innovation ensures that each restoration is not only life-like in appearance but also highly dependable and compatible, meeting the diverse needs of their clients with exceptional precision and care.

Purchasing their milling machines to bring their manufacturing in-house, has increased Atlas Dental Studio’s efficiency and versatility, improved the precision of their products and reduced costs.

Before

- Outsourced milling

- Dependent on the quality of their suppliers

- Timeline did not always align with the business needs

After

- Purchasing their milling machines to bring their manufacturing in-house, has increased Atlas Dental Studio’s efficiency and versatility, improved the precision of their products and reduced costs

- Reducing their dependency on outsourcing has allowed Atlas to maintain tighter controls over their production process improving their product quality, which has in-turn improved customer satisfaction ensuring a better overall experience for both Dental Professionals and their patients

- The combination of these benefits has given Atlas Dental Studio a competitive advantage

Atlas Dental Studio’s mission is to provide exceptional dental laboratory products and services that exceed their clients’ expectations, while fostering a culture of innovation, quality, and customer satisfaction.

Mindful that when referring to ‘customer satisfaction’ Atlas Dental Studio says their products must satisfy two audiences; they must meet the unique needs of the dental practices they supply, and ultimately deliver excellence to the patients receiving them.

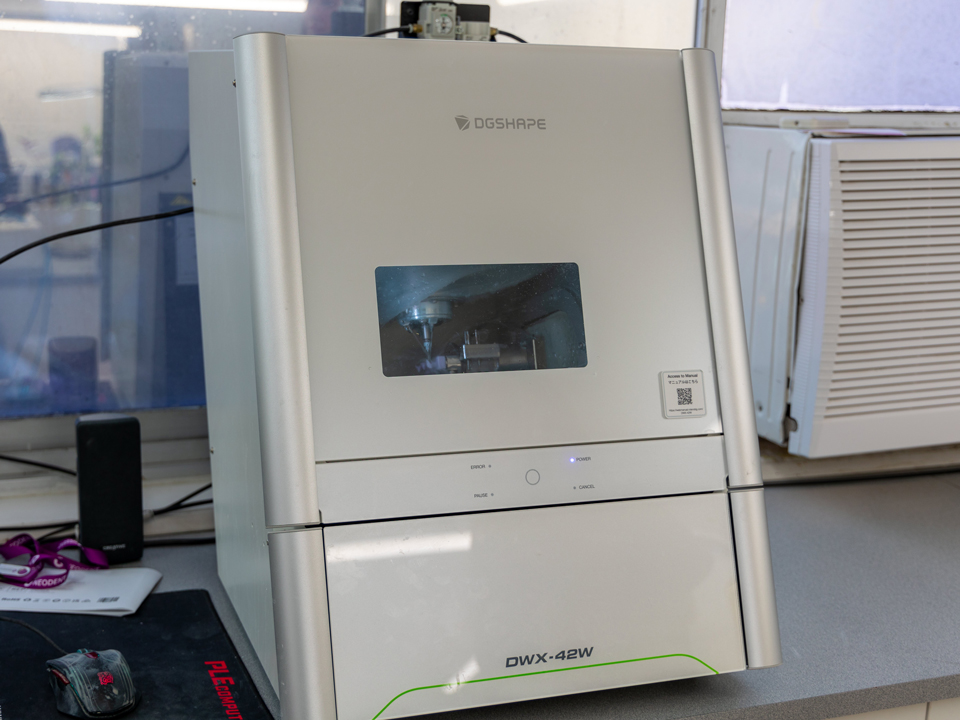

Offering their complete range of products, requires both wet and dry dental mills

Atlas Dental Studio produces crowns, bridges, inlays, onlays, veneers, abutments, and digital dentures that are either implant-supported or conventional. In addition, they manufacture a range of other products and services including appliances (retainers, splints, sports guards, and 3D printed surgical guides), implant planning, other custom devices, dental models for implant placement and other custom devices and applications.

Producing this extensive range of dental products requires skilled, experienced professional technicians using the most advanced, reliable and productive wet and dry dental milling machines.

Meticulous attention to detail

Louis Bowling, Master Technician at Atlas Dental Studio emphasises their commitment to maintaining the highest standard and precision in all aspects of their operations saying “their laboratory is equipped with advanced technology, CAD Software, CAM Software, 3D printers, and Scanning equipment, and they employ a rigorous quality control process to ensure that every product meets their exacting standards.”

Our laboratory is equipped with advanced technology, CAD Software, CAM Software, 3D printers, and Scanning equipment, and we employ a rigorous quality control process to ensure that every product meets our exacting standards.

Choosing the best mills

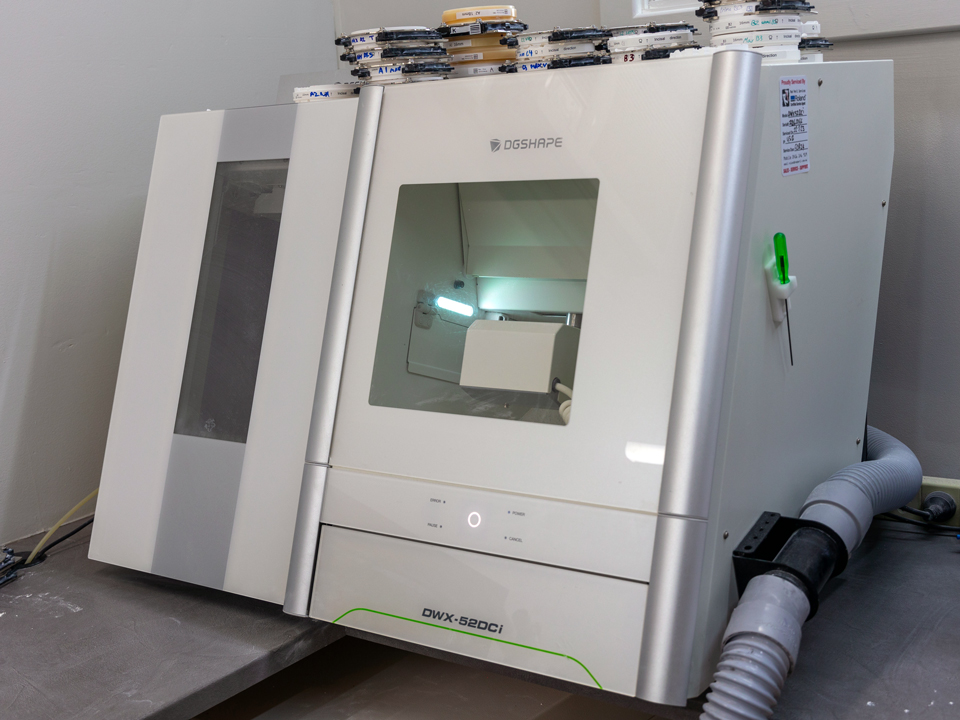

Atlas Dental Studio spent numerous months researching other companies’ milling machines before initially purchasing the DWX-52DCi and then later the DWX-42W Plus. According to Louis “they ultimately decided that Roland DG and “DGSHAPE was for them” due to many factors, including great online reviews from other laboratories, the quality of milled work and the reliability of the machines.”

Louis added “they also felt that the DGSHAPE machines were very competitively priced when comparing them to other machines and they had received great help from the Dealer they purchased their milling machines from.” Subsequently the ongoing support offered by DGSHAPE locally, has reinforced their decision to choose DGSHAPE.

Since making the investment, Atlas Dental Studio has been delighted with the quality and reliability of their mills motivating Louis to say, “they’re sturdy, well-built, offer very good accuracy and precision and produce high quality restorations. Precision is crucial in dental prosthetic production where even minor errors can affect the fit and function of the final product.”

“Our clients are very satisfied with what we’re producing and the number of new clients we’ve accumulated is outstanding.”

For more information on the products and services offered by Atlas Dental Studio head to their website.

Learn more about the advanced features of DGSHAPE dental mills here.