Dye sublimation is a digital printing technology that enables the reproduction of colourful images on common everyday items, including clothing and novelties. Prior to digital printing, reproducing images on these items (T-shirts being a typical example) required fairly involved and labour-intensive analogue processes, such as screen-printing.

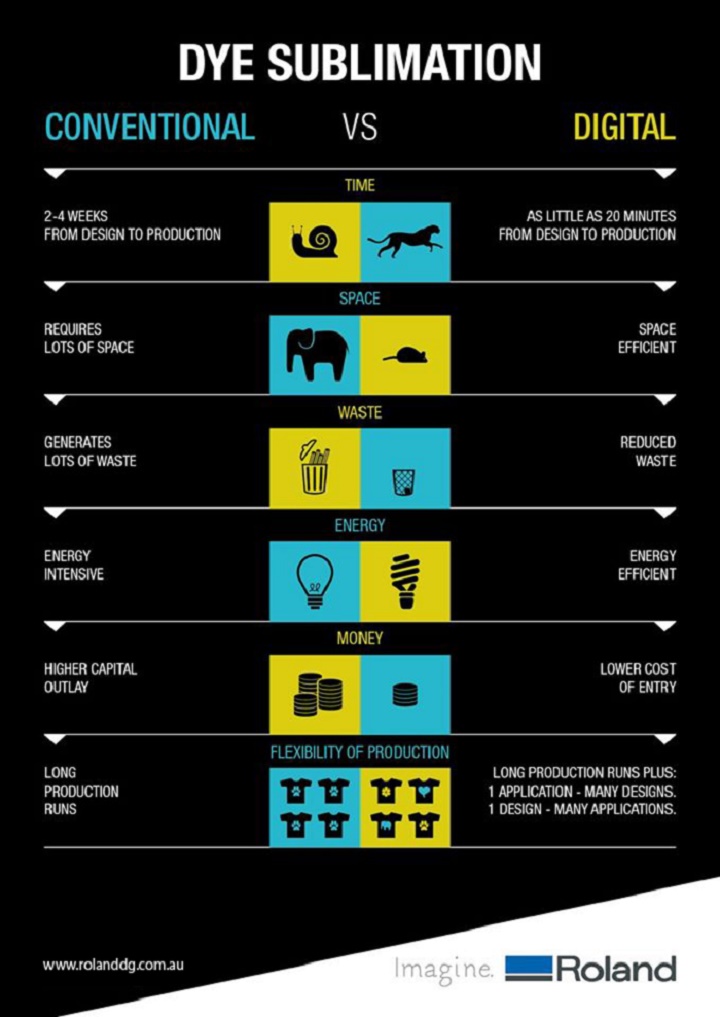

Saves Time

The modern dye sublimation process is quite simple in comparison to conventional methods. You create an image on your computer, print it onto special transfer paper using sublimation inks, and then apply the paper with the image to the item to be decorated. Using a heat press, the transfer paper is pressed onto the surface at 400 degrees Fahrenheit, which then causes the sublimation inks to “transfer” from the paper to any polymer fibres within the substrate. After less than a minute, the heat is removed and the transfer paper is peeled off, leaving behind a permanent, full colour image on the substrate. The whole process can take less than 20 minutes from design through to production.

Saves Space

Suitable printer types for dye sublimation work can range from a small desktop toner- or inkjet-based printers to medium-format inkjet printers. No longer are multiple, large printers required for printing to various materials.

Less Waste

Whilst digital dye sublimation printing does often involve the waste of the transfer paper (as the paper offers limited opportunities for re-use), reduced wastage occurs in the ability to produce both short and long runs of a required print.

Designs can effectively be “made to order” or samples can be produced conveniently and efficiently without having to waste extra materials or substrates.

Reduced Energy

Digital dye sublimation technology is constantly evolving and with this evolution comes even more efficient ways to sublimate. Earlier models required the user to physically change the inks to keep the print run going, but recent models such as the Texart XT-640 allow for unattended ink switching – no longer is the machine running idle until the ink has been switched but it can continuously run for hours of uninterrupted printing.

Furthermore, digital inkjet sublimation printing, in comparison with screen-based processes, requires minimal post-print washing. Printing with sublimation inks brings the advantages of easy wash, quick dry, and reduced creasing properties to significantly reduce the impact on the environment.

Costs Less

Analogue printing technology is not cost-effective when small quantities are involved, due to the immense amount of time preparing the artwork and the equipment for the production process. Therefore, if all you need is one, or even half a dozen items printed, analogue printing is going to be expensive and time-consuming.

With the introduction of inkjet printers in the 90’s, sublimation ink was formulated to work with various models of standard off-the-shelf desktop units. Using a relatively inexpensive printer, a computer and a heat press, anyone can now produce full-colour transfers cheaply and easily. The end result is a rapid conversion from analogue to digital printing techniques and from a world of mass production to mass customisation and personalisation.

Flexibility of Production

Digital printing, especially dye sublimation printing, is quick and inexpensive in both the setup and production, making it an ideal choice for creating personalised, one-of-a-kind items or for mass producing a variety of custom products. Moreover, dye sublimation printing yields beautiful and permanent colours that are embedded in the substrate or fabric, rather than printed on the surface. Images on fabric won’t fade or crack even after multiple washings. Images on hard substrates will not chip, peel or scratch.

Click here to find out more about our dye sublimation solutions or call one of our dye sublimation experts on 1800 500 119.